For more than eight decades, Allen Press has grown its reputation in the scholarly publishing and printing communities. Simply put, we’ve seen a lot of changes during our 80 years working for our customers in these industries. It’s been a great journey so far and we’re looking forward to what’s ahead.

-

2018

New Services. New Technologies. New Opportunities. Allen Press expands its capabilities, building a state-of-the-art digital production center, lettershop and in-house marketing agency to support the launch of comprehensive direct mail services.

-

2016

We unveil a new logo to showcase the authentic and personal approach we take towards our work. Making our customers’ stories come alive through quality printing and publisher services is done with a great deal of care and hard-earned expertise. We install a 6-unit web offset press to add efficiency and capacity. Exciting year, right?

-

2009

We start sharing lessons and tips with customers through our Best Practices webinars.

-

2007

This logo is introduced. The gold star symbolizes the high-quality service Allen Press gives to its customers.

-

1995

Knowing that the Internet would be a game changer, Allen Press starts offering online publishing and web hosting. -

1994

Rand Allen becomes the third generation of the Allen family to be president of Allen Press. -

1987

Harold’s son Arly takes over as president of Allen Press.

A four-color web offset printing press is installed. The press is geared to produce small magazines with press runs ranging from 10,000-100,000 copies. Bindery and mailing equipment is added. -

1986

For the second time, we outgrow our building. A former bean canning facility containing about 150,000 square feet of space is purchased and renovated to house all Allen Press operations.

-

1985

Customers and industry professionals attend the first educational seminar hosted by Allen Press in Lawrence, Kansas. -

1978

Computerized phototypesetting replaces the linotypes for setting type. -

1975

Allen Press has 21 linotype machines and 7 letterpresses manufactured by Heidelberg and Miller. The bindery consists of curved wooden tables where workers gathered printed signatures (16- or 32-page units) together by hand and use a stapling and gluing machine to add journal covers. This is cutting edge at the time.

-

1969

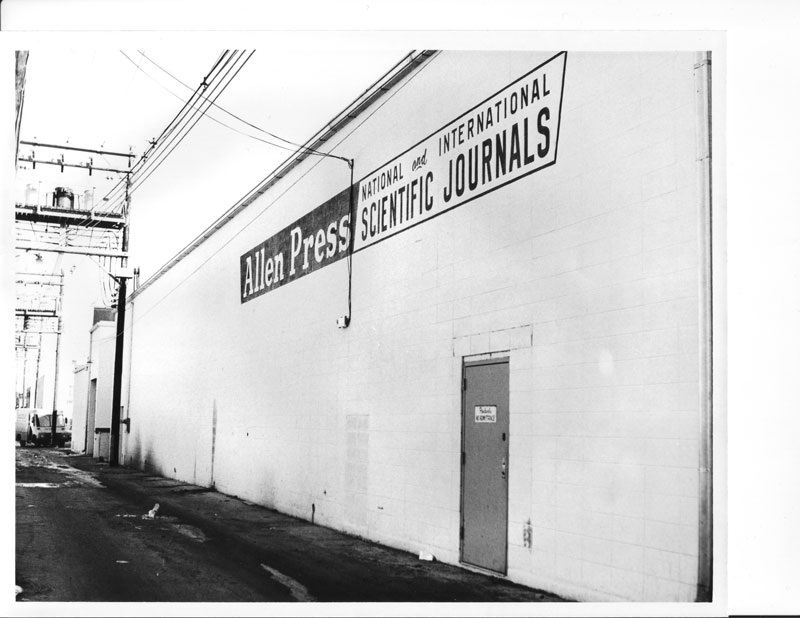

Allen Press purchases its first offset press, a Miehle. Its reputation in the scientific community grows based on printing detailed images and half-tones produced on an offset press. -

1960s

50% of Allen Press’ business comes from academic publications. Its work family grows to about 75 people. Many of its small society clients need help beyond typesetting, printing, binding, and mailing their publications, so back issue warehousing, fulfillment and mailing list services are added. All work was printed on letterpress machines.

-

1952

Dr. Harrison “Bud” Tordoff, a professor at KU, asks Harold Allen to bid on printing a scientific journal called The Wilson Bulletin. This relationship kicks off what becomes a deep connection between Allen Press and the academic community. -

1946

To make room for a growing team of workers and equipment, Allen Press moves to a larger plant near the corner of 11th and New Hampshire Streets on what is then outskirts of downtown Lawrence. -

1930s-1940s

The company cruised along as a small commercial letterpress print shop, working with and for the local Lawrence community from the basement of the First National Bank building at 8th and Massachusetts Streets (now Merchant’s Restaurant).

-

1935

Harold Allen purchases Seewir Printing and renames it Allen Press.

-

1925

Harold Allen becomes an apprentice to Charles Seewir at Seewir Printers while he is also a student at the University of Kansas. It is a classic apprenticeship with Seewir teaching Harold the trade in exchange for Harold’s labor.